Yayin da fasahar laser mai ƙarfi ke ci gaba da ci gaba cikin sauri, an yi amfani da Laser Diode Bars (LDBs) sosai a fannin sarrafa masana'antu, tiyatar likita, LiDAR, da kuma binciken kimiyya saboda yawan ƙarfinsu da kuma yawan haskensu mai yawa. Duk da haka, tare da ƙaruwar haɗakarwa da kuma ƙarfin aiki na kwakwalwan laser, ƙalubalen sarrafa zafi suna ƙara bayyana—wanda ke shafar daidaiton aiki da tsawon rayuwar laser.

Daga cikin dabarun sarrafa zafi daban-daban, Sanyayawar Contact Conduction ta fito fili a matsayin ɗaya daga cikin mahimman dabarun da aka saba amfani da su a cikin marufi na sandunan laser diode, godiya ga tsarinta mai sauƙi da kuma yawan watsawar zafi. Wannan labarin ya bincika ƙa'idodi, mahimman la'akari da ƙira, zaɓin kayan aiki, da kuma yanayin wannan "hanyar kwantar da hankali" zuwa sarrafa zafi a nan gaba.

1. Ka'idojin Sanyaya Hulɗa da Mu'amala

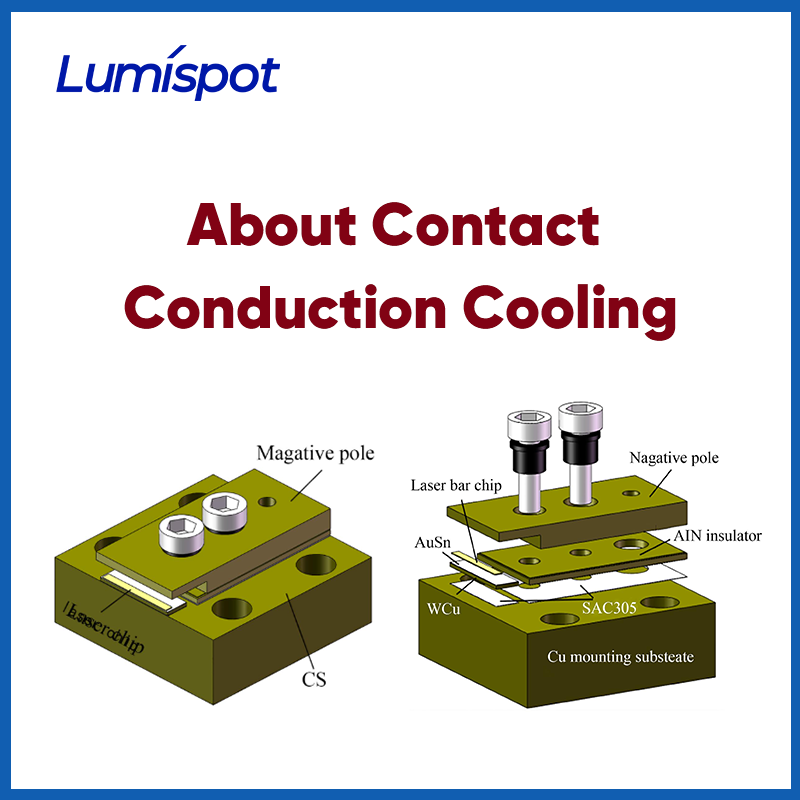

Kamar yadda sunan ya nuna, sanyayawar contact conduction tana aiki ta hanyar kafa hulɗa kai tsaye tsakanin guntuwar laser da wurin nutsewa na zafi, wanda ke ba da damar canja wurin zafi mai inganci ta hanyar kayan watsa zafi mai yawa da kuma watsawa cikin sauri zuwa muhallin waje.

①The HciPath:

A cikin sandar diode ta laser ta yau da kullun, hanyar zafi kamar haka:

Chip → Layin Solder → Submount (misali, jan ƙarfe ko yumbu) → TEC (Mai sanyaya Thermoelectric) ko Sink na Zafi → Muhalli na Yanayi

②Siffofi:

Wannan hanyar sanyaya tana da fasali:

Guduwar zafi mai yawa da kuma gajeren hanyar zafi, wanda ke rage zafin haɗuwa yadda ya kamata; Tsarin ƙarami, wanda ya dace da ƙananan marufi; Gudarwa mai wucewa, wanda ba ya buƙatar madaukai masu rikitarwa masu aiki na sanyaya.

2. Muhimman Abubuwan Da Za A Yi La'akari Da Su Don Ingantaccen Tsarin Zafi

Domin tabbatar da ingantaccen sanyayawar hanyar sadarwa, dole ne a yi la'akari da waɗannan fannoni yayin ƙirar na'urar:

① Juriyar Zafi a Haɗin Haɗin Solder

Tsarin watsa zafi na layin solder yana taka muhimmiyar rawa a cikin juriyar zafi gaba ɗaya. Ya kamata a yi amfani da ƙarfe masu yawan watsawa kamar ƙarfen AuSn ko indium mai tsarki, kuma ya kamata a sarrafa kauri da daidaiton layin solder don rage shingen zafi.

② Zaɓin Kayan Aiki na Submount

Kayan aikin submount na yau da kullun sun haɗa da:

Tagulla (Cu): Babban ƙarfin lantarki mai zafi, mai inganci da araha;

Tungsten Copper (WCu)/Molybdenum Copper (MoCu): Mafi kyawun daidaitawar CTE da kwakwalwan kwamfuta, yana ba da ƙarfi da juriya;

Aluminum Nitride (AlN): Kyakkyawan rufin lantarki, wanda ya dace da amfani da wutar lantarki mai ƙarfi.

③ Ingancin Hulɗar Fuskar

Rashin kyawun saman, lanƙwasa, da kuma danshi yana shafar ingancin canja wurin zafi kai tsaye. Sau da yawa ana amfani da gogewa da kuma shafa zinariya don inganta aikin hulɗar zafi.

④ Rage Hanya Mai Zafi

Tsarin ginin ya kamata ya yi nufin rage hanyar zafi tsakanin guntu da wurin nutsewar zafi. A guji matakan tsaka-tsaki marasa amfani don inganta ingancin watsa zafi gaba ɗaya.

3. Umarnin Ci Gaban Nan Gaba

Tare da ci gaba da ake samu wajen rage yawan amfani da wutar lantarki da kuma yawan amfani da wutar lantarki, fasahar sanyaya iskar contact conduction tana bunkasa ta wadannan hanyoyi:

① Haɗaɗɗen TIMs masu launuka da yawa

Haɗa hanyar sadarwa ta zafi ta ƙarfe tare da sassauƙan buffering don rage juriyar haɗin gwiwa da inganta juriyar zagayowar zafi.

② Marufi Mai Haɗakar Zafi

Tsarin ƙananan na'urori da na'urorin dumama a matsayin tsari guda ɗaya da aka haɗa don rage hanyoyin hulɗa da kuma ƙara ingancin canja wurin zafi a matakin tsarin.

③ Inganta Tsarin Bionic

Yin amfani da saman da ba a tsara su ba waɗanda ke kwaikwayon hanyoyin watsa zafi na halitta—kamar “gudanar da zafi kamar itace” ko “tsarin kama da sikelin”—don haɓaka aikin zafi.

④ Ikon Kula da Zafin Hankali

Haɗa na'urori masu auna zafin jiki da kuma sarrafa wutar lantarki mai ƙarfi don sarrafa zafi mai daidaitawa, yana tsawaita rayuwar aiki na na'urar.

4. Kammalawa

Ga sandunan laser diode masu ƙarfi, sarrafa zafi ba wai kawai ƙalubalen fasaha ba ne—tushe ne mai mahimmanci don aminci. Sanyayawar hanyar sadarwa, tare da halaye masu inganci, balagagge, kuma masu araha, har yanzu yana ɗaya daga cikin manyan hanyoyin magance matsalar watsa zafi a yau.

5. Game da Mu

A Lumispot, muna da ƙwarewa sosai a fannin marufi na laser diode, kimanta yanayin zafi, da kuma zaɓar kayan aiki. Manufarmu ita ce samar da mafita na laser mai inganci da tsawon rai wanda aka tsara don buƙatun aikace-aikacenku. Idan kuna son ƙarin bayani, muna maraba da ku da ku tuntube mu da ƙungiyarmu.

Lokacin Saƙo: Yuni-23-2025