Yi Subscribe a Social Media ɗinmu Domin Samun Labarai Masu Mahimmanci

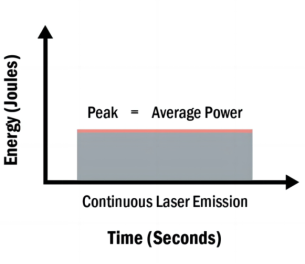

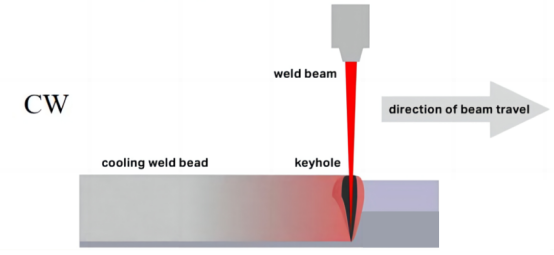

Ci gaba da Wave Laser

CW, wani suna na "Continuous Wave," yana nufin tsarin laser wanda ke da ikon samar da fitarwar laser ba tare da katsewa ba yayin aiki. An san shi da ikon fitar da laser akai-akai har sai aikin ya ƙare, ana bambanta lasers na CW ta hanyar ƙarancin ƙarfin kololuwarsu da matsakaicin ƙarfi mafi girma idan aka kwatanta da sauran nau'ikan lasers.

Aikace-aikace masu faɗi

Saboda ci gaba da aikin fitar da su, lasers na CW suna samun amfani mai yawa a fannoni kamar yanke ƙarfe da walda na tagulla da aluminum, wanda hakan ya sanya su cikin nau'ikan lasers da aka fi amfani da su kuma aka fi amfani da su. Ikonsu na samar da makamashi mai ɗorewa da daidaito yana sa su zama masu mahimmanci a duka yanayin sarrafawa daidai da yanayin samar da taro.

Sigogi na Daidaita Tsarin Aiki

Daidaita laser CW don ingantaccen aikin sarrafawa ya ƙunshi mai da hankali kan wasu mahimman sigogi, gami da tsarin ƙarfin lantarki, adadin defocus, diamita na tabo na katako, da saurin sarrafawa. Daidaita waɗannan sigogi yana da mahimmanci don cimma mafi kyawun sakamakon sarrafawa, tabbatar da inganci da inganci a cikin ayyukan injin laser.

Zane-zanen Makamashin Laser Mai Ci Gaba

Halayen Rarraba Makamashi

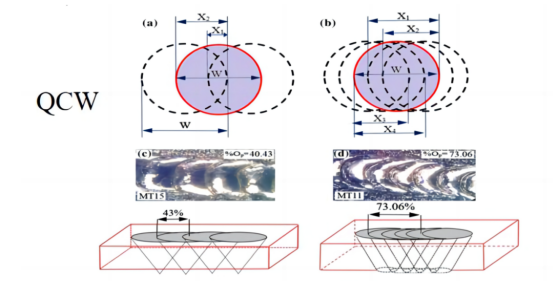

Wani abin lura na lasers na CW shine rarrabawar makamashin Gaussian, inda rarrabawar makamashin da ke tsakanin sassan hasken laser ke raguwa daga tsakiya zuwa waje a cikin tsarin rarrabawa na Gaussian (na yau da kullun). Wannan halayyar rarrabawa tana bawa lasers na CW damar cimma daidaito mai zurfi da ingancin sarrafawa, musamman a aikace-aikacen da ke buƙatar tura makamashi mai ƙarfi.

Zane-zanen Rarraba Makamashin Laser na CW

Fa'idodin Walda Laser Mai Ci gaba (CW)

Ra'ayin Tsarin Gine-gine

Binciken ƙananan tsarin ƙarfe yana nuna fa'idodi daban-daban na walda laser mai ci gaba da waƙar (CW) akan walda bugun Quasi-Continuous Wave (QCW). Walda bugun QCW, wanda aka iyakance shi da iyakar mitarsa, yawanci kusan 500Hz, yana fuskantar ciniki tsakanin ƙimar haɗuwa da zurfin shiga. Ƙarancin ƙimar haɗuwa yana haifar da rashin isasshen zurfin aiki, yayin da babban ƙimar haɗuwa yana iyakance saurin walda, yana rage inganci. Sabanin haka, walda laser CW, ta hanyar zaɓar diamita na tsakiya na laser da kawunan walda masu dacewa, yana cimma walda mai inganci da ci gaba. Wannan hanyar ta tabbatar da inganci musamman a aikace-aikacen da ke buƙatar babban amincin hatimi.

La'akari da Tasirin Zafi

Daga mahangar tasirin zafi, walda ta laser ta QCW pulse tana fama da matsalar haɗuwa, wanda ke haifar da dumama dinkin walda akai-akai. Wannan na iya haifar da rashin daidaito tsakanin ƙaramin tsarin ƙarfe da kayan iyaye, gami da bambance-bambancen girman katsewa da saurin sanyaya, wanda hakan ke ƙara haɗarin fashewa. Walda ta laser ta CW, a gefe guda, tana guje wa wannan matsalar ta hanyar samar da tsarin dumama mai daidaito da ci gaba.

Sauƙin Daidaitawa

Dangane da aiki da daidaitawa, walda laser QCW tana buƙatar gyara sigogi da yawa, ciki har da mitar maimaita bugun jini, ƙarfin kololuwa, faɗin bugun jini, zagayowar aiki, da ƙari. Walda laser CW yana sauƙaƙa tsarin daidaitawa, yana mai da hankali musamman kan yanayin raƙuman ruwa, gudu, ƙarfi, da adadin cire hankali, wanda hakan ke rage wahalar aiki sosai.

Ci gaban Fasaha a CW Laser Welding

Duk da cewa walda ta laser ta QCW an san ta da ƙarfinta mai girma da ƙarancin shigar zafi, tana da amfani ga abubuwan da ke da zafi da kuma kayan da ke da sirara sosai, ci gaba a fasahar walda ta laser ta CW, musamman don aikace-aikacen wutar lantarki mai ƙarfi (yawanci sama da watts 500) da walda mai zurfi bisa ga tasirin ramin maɓalli, sun faɗaɗa kewayon aikace-aikacenta da ingancinta sosai. Wannan nau'in laser ya dace musamman ga kayan da suka fi kauri fiye da 1mm, suna cimma babban rabo na al'amari (sama da 8:1) duk da yawan shigar zafi.

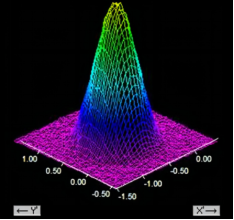

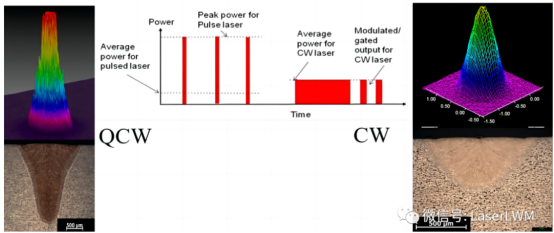

Walda ta Laser Mai Ci gaba (QCW)

Rarraba Makamashi Mai Mayar da Hankali

QCW, wanda ke tsaye ga "Quasi-Continuous Wave," yana wakiltar fasahar laser inda laser ke fitar da haske ta hanyar da ba ta canzawa ba, kamar yadda aka nuna a hoto na a. Ba kamar rarrabawar makamashi iri ɗaya na lasers masu ci gaba ɗaya ba, lasers na QCW suna tattara kuzarinsu sosai. Wannan halayyar tana ba lasers na QCW damar samun ƙarfin kuzari mafi girma, wanda ke fassara zuwa ƙarfin shigar ciki mai ƙarfi. Sakamakon tasirin ƙarfe yana kama da siffar "ƙusa" tare da babban rabo na zurfin-zuwa-faɗi, yana bawa lasers na QCW damar yin fice a aikace-aikace da suka haɗa da ƙarfe masu haske mai yawa, kayan da ke da saurin zafi, da kuma walda mai daidaito.

Ingantaccen Kwanciyar Hankali da Rage Tsangwama a Plume

Ɗaya daga cikin fa'idodin walda laser na QCW shine ikonsa na rage tasirin ƙarfen da ke kan yawan shan kayan, wanda ke haifar da tsari mai ƙarfi. A lokacin hulɗar kayan laser, ƙaiƙayi mai ƙarfi na iya haifar da cakuda tururin ƙarfe da plasma a saman wurin narkewa, wanda aka fi sani da ƙarfen da ke ɗauke da ƙarfen. Wannan ƙarfen zai iya kare saman kayan daga laser, yana haifar da isar da wutar lantarki mara ƙarfi da lahani kamar fesawa, wuraren fashewa, da ramuka. Duk da haka, fitar da lasers na QCW akai-akai (misali, fashewar 5ms bayan dakatarwa ta 10ms) yana tabbatar da cewa kowace bugun laser ya isa saman kayan ba tare da taɓa bututun ƙarfe ba, wanda ke haifar da ingantaccen tsarin walda, musamman ma mai amfani ga walda mai siriri.

Tsarin Ruwa Mai Tsabta

Tsarin narkewar wurin narkewar, musamman dangane da ƙarfin da ke aiki a kan maɓalli, yana da matuƙar muhimmanci wajen tantance ingancin walda. Na'urorin laser masu ci gaba, saboda tsawon lokacin da suke ɗauka da kuma manyan wuraren da zafi ke shafar su, suna haifar da manyan wuraren narkewar da aka cika da ƙarfe mai ruwa. Wannan na iya haifar da lahani da ke da alaƙa da manyan wuraren narkewar, kamar rugujewar ramin maɓalli. Sabanin haka, kuzarin da aka mayar da hankali da kuma ɗan gajeren lokacin hulɗa na walda laser na QCW suna tattara wurin narkewar a kusa da ramin maɓalli, wanda ke haifar da rarraba ƙarfi iri ɗaya da kuma ƙarancin yawan porosity, fashewa, da kuma fashewa.

Yankin da Ya Shafi Zafi (HAZ)

Na'urorin walda na laser masu ci gaba suna sanya kayan aiki su zama masu zafi mai ɗorewa, wanda ke haifar da kwararar zafi mai yawa zuwa cikin kayan. Wannan na iya haifar da lalacewar zafi mara kyau da lahani da ke haifar da damuwa a cikin kayan siriri. Na'urorin walda na QCW, tare da aikinsu na ɗan lokaci, suna ba da damar kayan su huta, don haka rage yankin da zafi ya shafa da shigarwar zafi. Wannan yana sa walda na laser na QCW ya dace musamman ga kayan siriri da waɗanda ke kusa da abubuwan da ke da saurin zafi.

Ƙarfin Kololuwa Mafi Girma

Duk da cewa suna da matsakaicin ƙarfi iri ɗaya da na'urorin laser masu ci gaba, na'urorin QCW suna samun ƙarfin kololuwa mafi girma da yawan kuzari, wanda ke haifar da zurfafa shiga da ƙarfin walda mai ƙarfi. Wannan fa'ida tana bayyana musamman a cikin walda na siraran zanen ƙarfe da aluminum. Sabanin haka, na'urorin laser masu ci gaba da ƙarfin iri ɗaya na iya kasa yin alama a saman kayan saboda ƙarancin yawan kuzari, wanda ke haifar da tunani. Na'urorin laser masu ci gaba da ƙarfi, duk da cewa suna iya narke kayan, na iya fuskantar ƙaruwa mai ƙarfi a cikin yawan sha bayan narkewa, wanda ke haifar da zurfin narkewa da shigarwar zafi mara sarrafawa, wanda bai dace da walda mai sirara ba kuma yana iya haifar da ko dai babu alama ko ƙonewa, rashin cika buƙatun tsari.

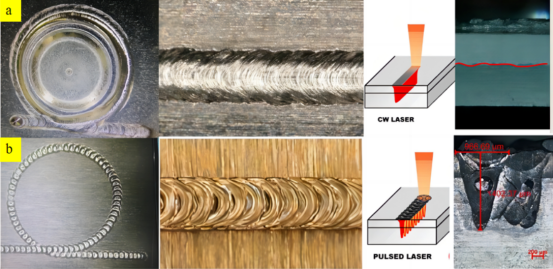

Kwatanta sakamakon walda tsakanin lasers CW da QCW

a. Laser mai ci gaba da Wave (CW):

- Bayyanar ƙusa da aka rufe da laser

- Bayyanar dinkin walda madaidaiciya

- Tsarin zane na fitar da hasken laser

- Sashen giciye mai tsayi

b. Laser mai ci gaba da juyawa (QCW):

- Bayyanar ƙusa da aka rufe da laser

- Bayyanar dinkin walda madaidaiciya

- Tsarin zane na fitar da hasken laser

- Sashen giciye mai tsayi

- * Tushe: Labarin Willdong, ta hanyar WeChat Public Account LaserLWM.

- * Asalin hanyar haɗin labarin: https://mp.weixin.qq.com/s/8uCC5jARz3dcgP4zusu-FA.

- An tanadar da abubuwan da ke cikin wannan labarin ne kawai don ilmantarwa da sadarwa, kuma duk haƙƙin mallaka na asalin marubucin ne. Idan akwai keta haƙƙin mallaka, tuntuɓi don cire shi.

Lokacin Saƙo: Maris-05-2024