| Mai haɗa murfin Tarin sandunan Diode Laser | An cika AuSn |

| Tsakiyar Zangon Ra'ayi | 1064nm |

| Ƙarfin Fitarwa | ≥55W |

| Aikin Yanzu | ≤30 A |

| Aiki Voltage | ≤24V |

| Yanayin Aiki | CW |

| Tsawon Kogo | 900mm |

| Madubin Fitarwa | T = 20% |

| Zafin Ruwa | 25±3℃ |

Yi Subscribe a Social Media ɗinmu Domin Samun Labarai Masu Mahimmanci

Bukatar na'urorin laser masu amfani da diode-pumped CW (Continuous Wave) suna ƙaruwa da sauri a matsayin tushen famfo mai mahimmanci ga lasers masu amfani da diode-state. Waɗannan na'urorin suna ba da fa'idodi na musamman don biyan takamaiman buƙatun aikace-aikacen laser mai amfani da diode-state. G2 - Laser ɗin Diode Pump Solid State, sabon samfurin CW Diode Pump Series daga LumiSpot Tech, yana da fa'idar aikace-aikace da kuma ƙwarewar aiki mafi kyau.

A cikin wannan labarin, za mu haɗa da abubuwan da ke mai da hankali kan aikace-aikacen samfurin, fasalulluka na samfura, da fa'idodin samfura game da laser ɗin famfo na diode na CW. A ƙarshen labarin, zan nuna rahoton gwaji na CW DPL daga Lumispot Tech da fa'idodinmu na musamman.

Filin Aikace-aikacen

Ana amfani da na'urorin laser masu ƙarfin lantarki masu ƙarfi sosai a matsayin tushen famfo don na'urorin laser masu ƙarfi. A aikace, tushen na'urar laser diode-pumping ta semiconductor shine mabuɗin inganta fasahar laser mai ƙarfi na laser diode-pumping.

Wannan nau'in laser yana amfani da na'urar laser semiconductor tare da fitarwa mai tsayayyen tsayi maimakon fitilar Krypton ko Xenon ta gargajiya don fitar da lu'ulu'u. Sakamakon haka, ana kiran wannan laser da aka inganta da 2ndSamar da na'urar laser ta famfon CW (G2-A), wadda ke da halaye na inganci mai yawa, tsawon rai na aiki, ingancin hasken rana mai kyau, kwanciyar hankali mai kyau, ƙanƙantawa da kuma rage girman hasken.

Ƙarfin Famfo Mai Ƙarfi

Tushen Pump na CW Diode yana ba da babban fashewar ƙarfin kuzarin gani, yana fitar da matsakaicin riba a cikin laser ɗin solid-state, don cimma mafi kyawun aikin laser ɗin solid-state. Hakanan, ƙarfinsa mai ƙarfi (ko matsakaicin ƙarfi) yana ba da damar amfani da dama a cikinmasana'antu, magani, da kimiyya.

Kyakkyawan haske da kwanciyar hankali

Module ɗin laser na famfo na semiconductor na CW yana da ingancin hasken haske, tare da kwanciyar hankali kwatsam, wanda yake da mahimmanci don cimma daidaitaccen fitowar hasken laser. An tsara na'urorin don samar da ingantaccen bayanin haske mai ƙarfi, wanda ke tabbatar da ingantaccen famfo na laser mai ƙarfi. Wannan fasalin ya cika buƙatun aikace-aikacen laser a cikin sarrafa kayan masana'antu. yanke laser, da kuma R&D.

Ci gaba da Aikin Raƙuman Ruwa

Yanayin aiki na CW ya haɗa fa'idodin laser mai tsayin daka mai ci gaba da kuma Laser mai ƙarfin Pulsed. Babban bambanci tsakanin Laser CW da Laser mai ƙarfin Pulsed shine fitowar wutar lantarki.CW Laser, wanda kuma aka sani da Continuous wave laser, yana da halaye na yanayin aiki mai karko da kuma ikon aika ci gaba da wave.

Tsarin Karami Mai Inganci

Ana iya haɗa CW DPL cikin sauƙi cikin na'urar lantarkiLaser mai ƙarfiya danganta da ƙaramin tsari da tsarin. Tsarin gininsu mai ƙarfi da ingantattun kayan aikin suna tabbatar da aminci na dogon lokaci, rage farashin lokacin hutu da kulawa, wanda yake da mahimmanci musamman a masana'antu da hanyoyin likita.

Bukatar Kasuwa ta Jerin DPL - Ƙara Samun Damar Kasuwa

Yayin da buƙatar laser mai ƙarfi ke ci gaba da faɗaɗa a fannoni daban-daban na masana'antu, haka nan buƙatar hanyoyin famfo masu ƙarfi kamar na'urorin laser mai ƙarfin CW diode. Masana'antu kamar masana'antu, kiwon lafiya, tsaro, da binciken kimiyya sun dogara ne da laser mai ƙarfi don aikace-aikacen daidaito.

A taƙaice, a matsayin tushen famfon diode na laser mai ƙarfi, halayen samfuran: ƙarfin famfon mai ƙarfi, yanayin aiki na CW, ingantaccen ingancin katako da kwanciyar hankali, da ƙirar tsari mai ƙanƙanta, suna ƙara buƙatar kasuwa a cikin waɗannan na'urorin laser. A matsayin mai samar da kayayyaki, Lumispot Tech kuma tana ba da ƙoƙari sosai wajen inganta aiki da fasahar da aka yi amfani da su a cikin jerin DPL.

Saitin Samfurin G2-A DPL Daga Lumispot Tech

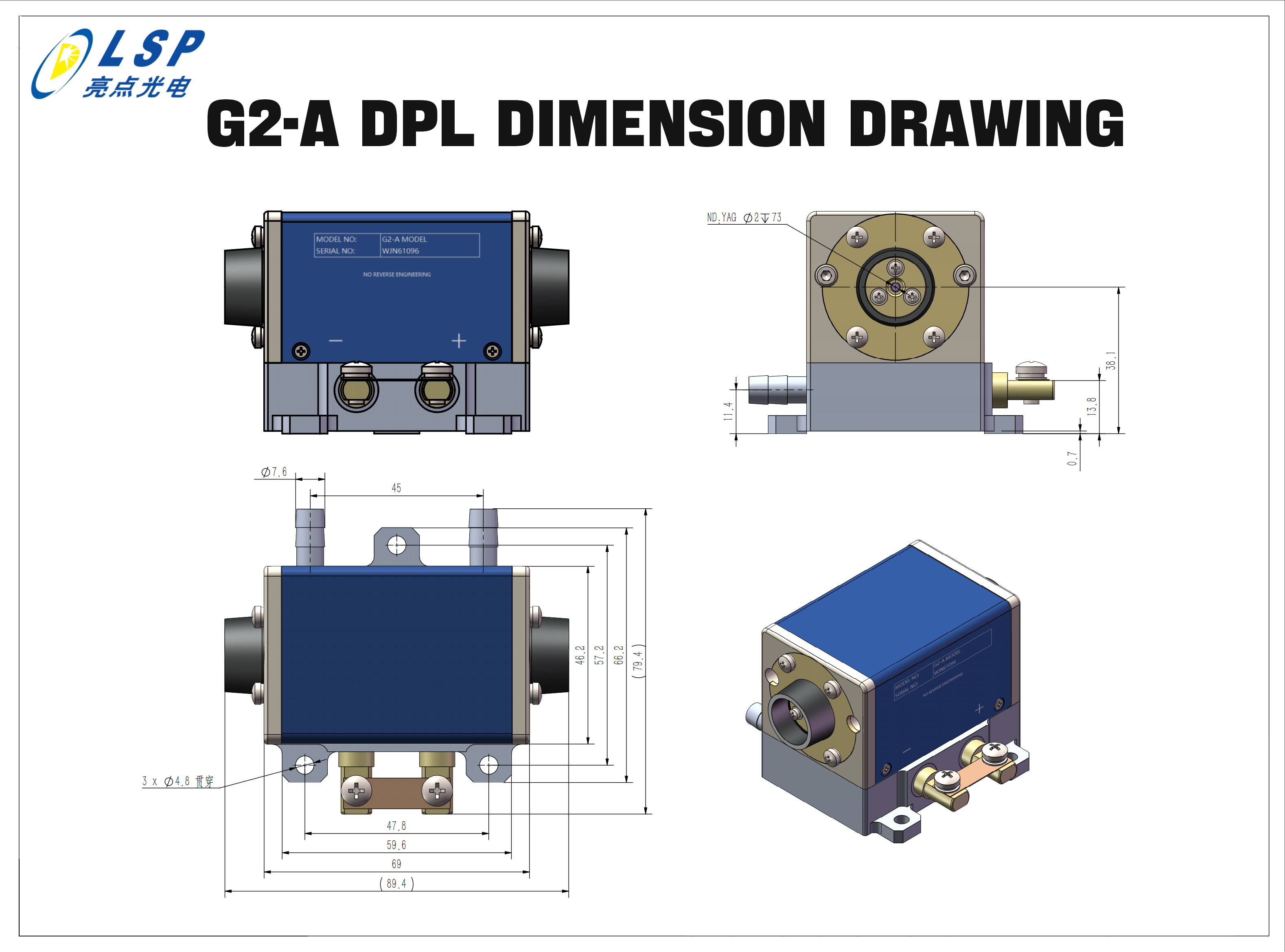

Kowace saitin samfura ta ƙunshi rukunoni uku na na'urori masu jerin a kwance, kowace rukuni na na'urorin Horizontal Stacked Array ƙarfin famfo na kimanin 100W@25A, da kuma ƙarfin famfo na gaba ɗaya na 300W@25A.

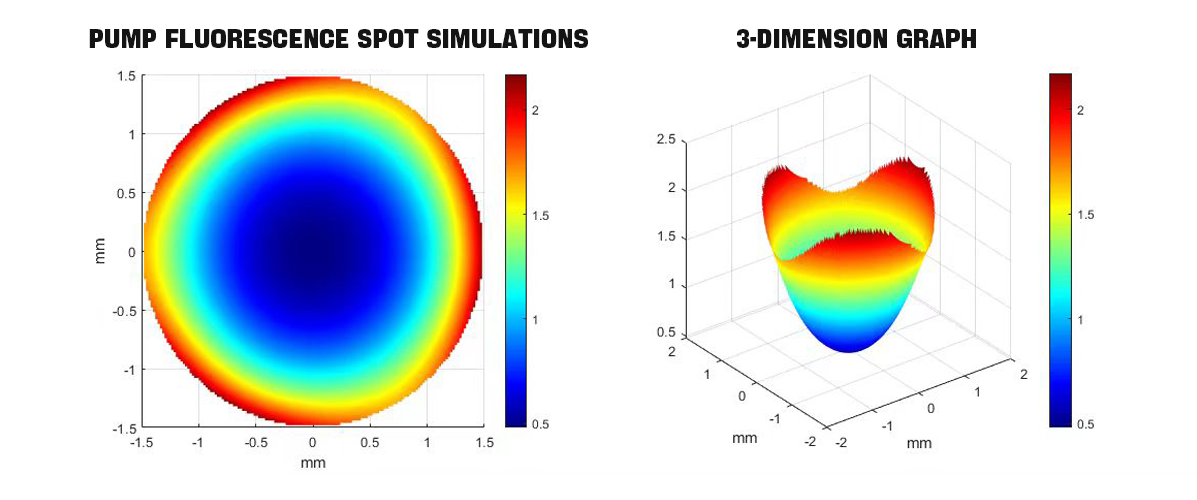

An nuna wurin hasken famfo na G2-A a ƙasa:

Babban Bayanan Fasaha na G2-A Diode Pump Solid State Laser:

Ƙarfinmu a Fasahohin Fasaha

1. Fasahar Gudanar da Zafin Jiki ta Canji

Ana amfani da na'urorin laser masu ƙarfi na Semiconductor da aka yi amfani da su sosai don aikace-aikacen wave mai ci gaba (CW) tare da babban fitarwar wutar lantarki mai tsayi da aikace-aikacen wave mai ci gaba (CW) tare da matsakaicin fitarwar wutar lantarki mai yawa. A cikin waɗannan na'urorin laser, tsayin wurin nutsewar zafi da nisan da ke tsakanin na'urori (watau, kauri na substrate da na'urar) suna tasiri sosai ga ikon watsa zafi na samfurin. Babban nisan guntu-zuwa-guntu yana haifar da mafi kyawun watsa zafi amma yana ƙara girman samfurin. Akasin haka, idan aka rage tazara tsakanin na'urori, girman samfurin zai ragu, amma ƙarfin watsa zafi na samfurin bazai isa ba. Amfani da ƙaramin girma don tsara mafi kyawun laser mai ƙarfi na semiconductor wanda ya cika buƙatun watsa zafi aiki ne mai wahala a cikin ƙira.

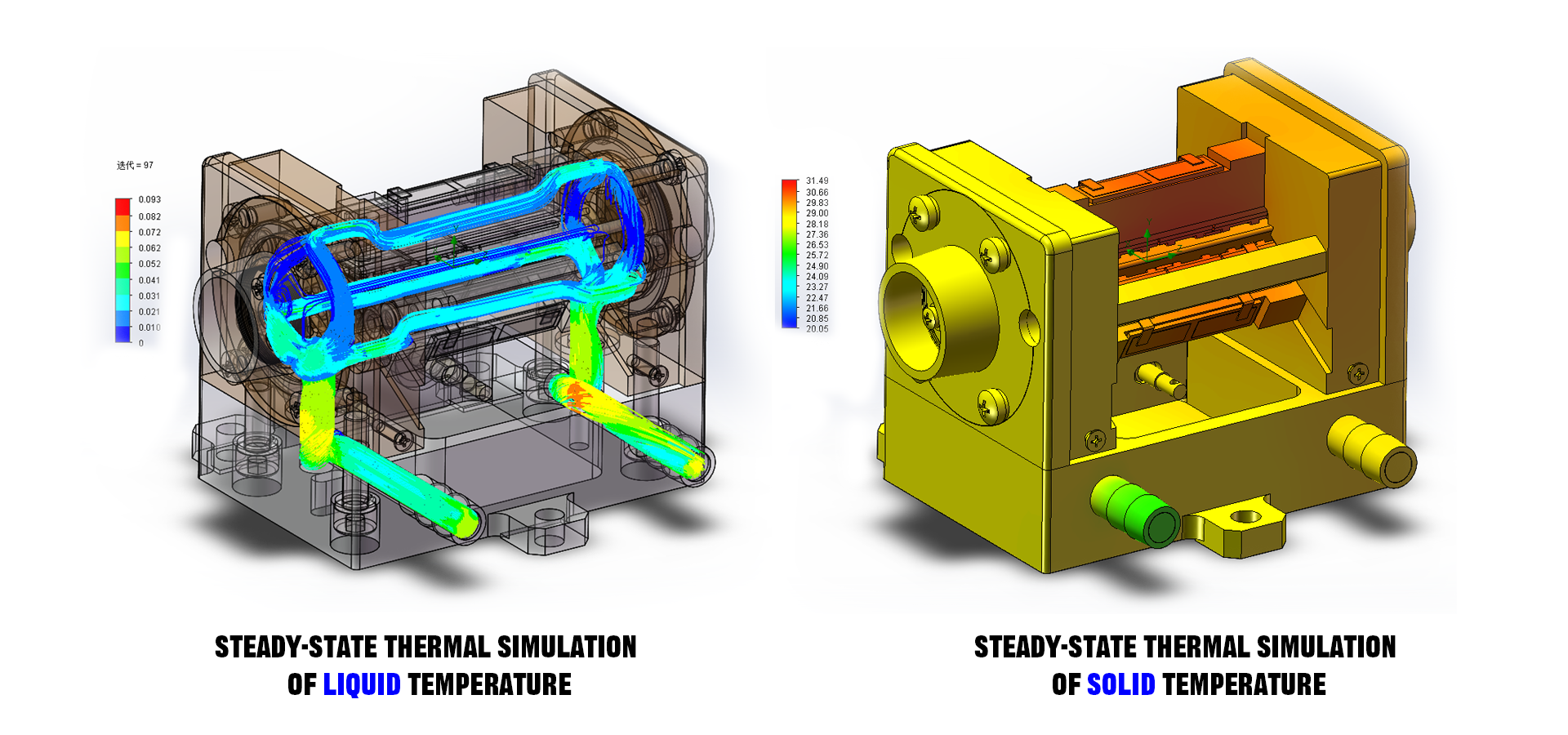

Jadawalin Kwaikwayon Yanayin Dare Mai Tsayayye

Lumispot Tech tana amfani da hanyar ƙayyadadden abu don kwaikwayon da ƙididdige filin zafin na'urar. Ana amfani da haɗin kwaikwayon yanayin zafi mai ƙarfi na canja wurin zafi mai ƙarfi da kwaikwayon yanayin zafi na ruwa don kwaikwayon yanayin zafi. Don yanayin aiki mai ci gaba, kamar yadda aka nuna a cikin hoton da ke ƙasa: an ba da shawarar samfurin ya sami mafi kyawun tazara da tsari a ƙarƙashin yanayin kwaikwayon yanayin zafi mai ƙarfi na canja wurin zafi mai ƙarfi. A ƙarƙashin wannan tazara da tsari, samfurin yana da kyakkyawan ikon watsa zafi, ƙarancin zafin jiki mai ƙarfi, da kuma mafi ƙarancin halayyar.

2.AuSn soldertsarin tattarawa

Kamfanin Lumispot Tech yana amfani da dabarar marufi wadda ke amfani da solder AnSn maimakon solder na gargajiya na indium don magance matsalolin da suka shafi gajiyar zafi, ƙaura ta lantarki, da ƙaura ta wutar lantarki da zafi da solder indium ke haifarwa. Ta hanyar amfani da solder AuSn, kamfaninmu yana da nufin haɓaka amincin samfura da tsawon rai. Ana yin wannan maye gurbin yayin da ake tabbatar da tazara tsakanin sandunan sanduna akai-akai, wanda hakan ke ƙara ba da gudummawa ga inganta amincin samfura da tsawon rai.

A cikin fasahar marufi na laser mai ƙarfin lantarki mai ƙarfin semiconductor, masana'antun ƙasashen duniya sun ɗauki ƙarfe na indium (In) a matsayin kayan walda saboda fa'idodinsa na ƙarancin narkewar wuri, ƙarancin damuwa na walda, sauƙin aiki, da kuma kyakkyawan nakasa da shigar filastik. Duk da haka, ga lasers mai ƙarfi na semiconductor da aka tura a ƙarƙashin yanayin aiki mai ci gaba, matsin lamba mai canzawa zai haifar da gajiyar damuwa na layin walda na indium, wanda zai haifar da gazawar samfur. Musamman a cikin yanayin zafi mai yawa da ƙasa da faɗin bugun jini mai tsawo, ƙimar gazawar walda na indium a bayyane take.

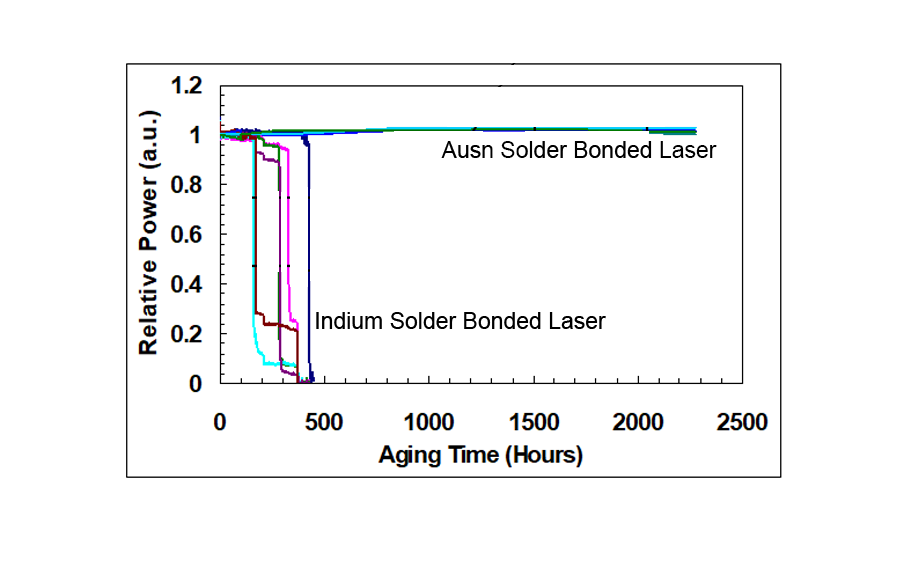

Kwatanta gwaje-gwajen rayuwa masu sauri na lasers tare da fakitin solder daban-daban

Bayan awanni 600 na tsufa, duk samfuran da aka lulluɓe da indium solder sun lalace; yayin da samfuran da aka lulluɓe da tin na zinare suna aiki na tsawon awanni sama da 2,000 ba tare da wani canji a cikin ƙarfi ba; suna nuna fa'idodin encapsulation na AuSn.

Domin inganta ingancin na'urorin laser masu ƙarfin gaske tare da kiyaye daidaiton alamun aiki daban-daban, Lumispot Tech ta ɗauki Hard Solder (AuSn) a matsayin sabon nau'in kayan marufi. Amfani da ma'aunin ma'aunin faɗaɗa zafi (CTE-Matched Submount), ingantaccen sakin damuwa na zafi, kyakkyawan mafita ga matsalolin fasaha da za a iya fuskanta yayin shirya na'urar solder mai tauri. Sharaɗin da ake buƙata don kayan substrate (submount) su sami damar haɗawa da guntu na semiconductor shine na'urar metallisation ta saman. Na'urar metallisation ta saman shine ƙirƙirar wani Layer na shingen watsawa da kuma Layer infiltration na solder a saman kayan substrate.

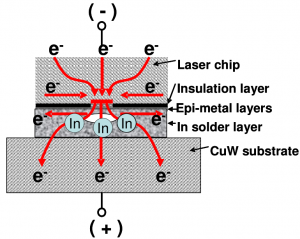

Zane-zanen tsarin ƙaura ta lantarki na na'urar laser da aka lulluɓe a cikin indium solder

Domin inganta ingancin na'urorin laser masu ƙarfin gaske tare da kiyaye daidaiton alamun aiki daban-daban, Lumispot Tech ta ɗauki Hard Solder (AuSn) a matsayin sabon nau'in kayan marufi. Amfani da ma'aunin ma'aunin faɗaɗa zafi (CTE-Matched Submount), ingantaccen sakin damuwa na zafi, kyakkyawan mafita ga matsalolin fasaha da za a iya fuskanta yayin shirya na'urar solder mai tauri. Sharaɗin da ake buƙata don kayan substrate (submount) su sami damar haɗawa da guntu na semiconductor shine na'urar metallisation ta saman. Na'urar metallisation ta saman shine ƙirƙirar wani Layer na shingen watsawa da kuma Layer infiltration na solder a saman kayan substrate.

Manufarta ita ce a gefe guda a toshe hanyar da za a iya haɗa ta da kayan substrate, a gefe guda kuma a ƙarfafa ta da ƙarfin walda na kayan substrate, don hana layin mai walƙiya na ramin. Ƙarfin ƙarfe na saman kuma zai iya hana iskar shaka da kutsewar danshi na kayan substrate, rage juriyar hulɗa a cikin aikin walda, don haka inganta ƙarfin walda da amincin samfura. Amfani da mai walƙiya mai tauri AuSn azaman kayan walda don lasers na semiconductor da aka ɗora da ƙarfi na iya hana gajiyar damuwa ta indium, iskar shaka da ƙaura ta electro-thermal da sauran lahani, wanda hakan ke inganta ingancin lasers na semiconductor da kuma tsawon rayuwar laser. Amfani da fasahar rufe tin na zinare zai iya shawo kan matsalolin ƙaura ta lantarki da ƙaura ta electrothermal na indium solder.

Mafita Daga Lumispot Tech

A cikin na'urorin laser masu ci gaba ko masu bugun jini, zafi da aka samu sakamakon shaƙar hasken famfo ta hanyar laser da kuma sanyayawar waje ta matsakaici yana haifar da rashin daidaituwar rarraba zafin jiki a cikin injin laser, wanda ke haifar da canje-canje a cikin ma'aunin refractive na matsakaici sannan ya haifar da tasirin zafi daban-daban. Ajiye zafi a cikin injin gain yana haifar da tasirin ruwan tabarau na zafi da tasirin birefringence da aka haifar da zafi, wanda ke haifar da wasu asara a cikin tsarin laser, yana shafar kwanciyar hankali na laser a cikin rami da ingancin hasken fitarwa. A cikin tsarin laser mai ci gaba da aiki, damuwar zafi a cikin injin gain yana canzawa yayin da ƙarfin famfo ke ƙaruwa. Tasirin zafi daban-daban a cikin tsarin yana shafar tsarin laser gaba ɗaya don samun ingantaccen ingancin haske da ƙarfin fitarwa mafi girma, wanda shine ɗayan matsalolin da za a magance. Yadda za a hana da rage tasirin zafi na lu'ulu'u a cikin aikin, masana kimiyya sun daɗe suna cikin damuwa, ya zama ɗaya daga cikin wuraren bincike na yanzu.

Laser na Nd:YAG tare da ramin ruwan tabarau na thermal

A cikin aikin haɓaka na'urorin laser na Nd:YAG masu ƙarfin LD mai ƙarfi, an warware na'urorin laser na Nd:YAG masu ramin ruwan tabarau na thermal, ta yadda na'urar za ta iya samun babban ƙarfi yayin da take samun babban ingancin hasken.

A cikin wani aiki na haɓaka na'urar laser mai ƙarfin LD mai ƙarfin Nd:YAG, Lumispot Tech ta ƙirƙiro na'urar G2-A, wadda ke magance matsalar ƙarancin wutar lantarki saboda ramuka masu ɗauke da ruwan tabarau na thermal, wanda ke ba da damar na'urar ta sami babban ƙarfi tare da ingancin hasken rana mai ƙarfi.

Lokacin Saƙo: Yuli-24-2023