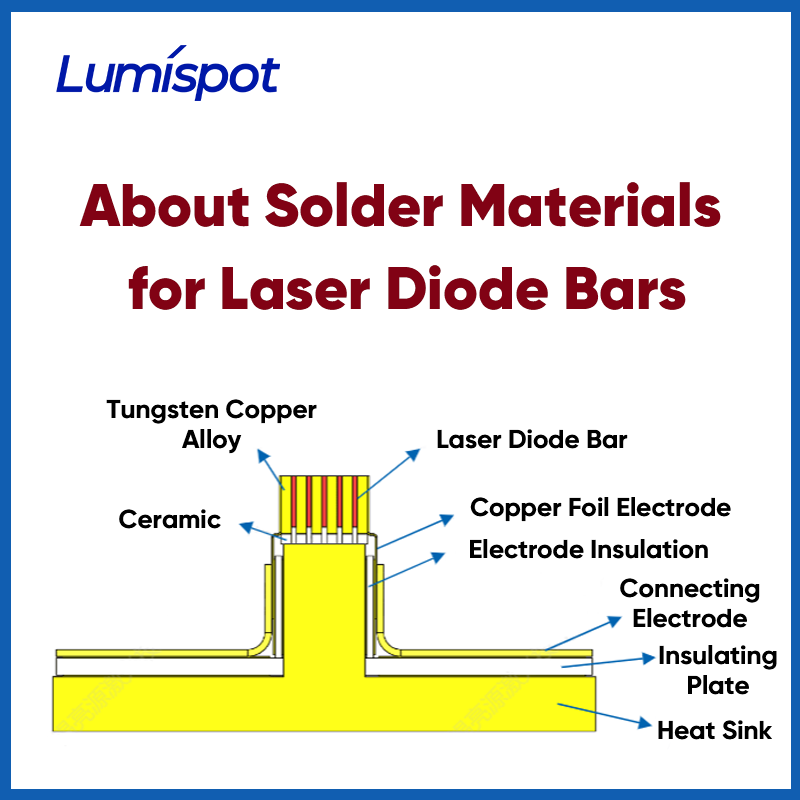

A cikin ƙira da ƙera na'urorin laser masu ƙarfin lantarki, sandunan diode na laser suna aiki a matsayin manyan na'urorin fitar da haske. Ayyukansu ba wai kawai ya dogara ne akan ingancin na'urorin laser ba, har ma da tsarin marufi. Daga cikin sassa daban-daban da ke cikin marufi, kayan solder suna taka muhimmiyar rawa a matsayin haɗin zafi da lantarki tsakanin guntu da wurin nutsewa na zafi.

1. Matsayin Mai Solder a Sandunan Laser Diode

Sandunan diode na Laser galibi suna haɗa na'urori masu fitar da iska da yawa, wanda ke haifar da yawan ƙarfi da kuma tsauraran buƙatun sarrafa zafi. Domin cimma ingantaccen watsa zafi da kwanciyar hankali, kayan solder dole ne su cika waɗannan sharuɗɗa:

① Babban ƙarfin lantarki na thermal:

Yana tabbatar da ingantaccen canja wurin zafi daga guntuwar laser.

② Kyakkyawan danshi:

Yana samar da matsewar haɗin gwiwa tsakanin guntu da substrate.

③ Wurin narkewa mai dacewa:

Yana hana sake kwarara ko lalacewa yayin sarrafawa ko aiki na gaba.

④ Daidaitaccen ma'aunin faɗaɗa zafi (CTE):

Yana rage matsin lamba na zafi akan guntu.

⑤ Kyakkyawan juriya ga gajiya:

Yana tsawaita rayuwar na'urar.

2. Nau'ikan Solder da Aka Fi Soda Don Marufi na Laser Bar

Ga manyan nau'ikan kayan solder guda uku da ake amfani da su a cikin marufi na sandunan diode na laser:

①Alloy na Zinare-Tin (AuSn)

Kadarorin:

Tsarin Eutectic na 80Au/20Sn tare da wurin narkewa na 280°C; yawan watsawar zafi da ƙarfin injina.

Fa'idodi:

Kyakkyawan kwanciyar hankali mai zafi, tsawon lokacin gajiyar zafi, babu gurɓataccen halitta, babban aminci

Aikace-aikace:

Tsarin laser na masana'antu na soja, sararin samaniya, da kuma manyan injinan sarrafa laser.

②Tsarkakken Indium (In)

Kadarorin:

Yanayin narkewa na 157°C; mai laushi kuma mai sauƙin sassauƙa.

Fa'idodi:

Kyakkyawan aikin hawan zafi, ƙarancin damuwa akan guntu, ya dace da kare tsarin sassauƙa, ya dace da buƙatun haɗin ƙananan zafin jiki

Iyakoki:

Yana da saurin kamuwa da iskar shaka; yana buƙatar yanayi mara aiki yayin sarrafawa, ƙarancin ƙarfin injina; ba shi da kyau don aikace-aikacen da ke ɗauke da kaya mai yawa.

③Tsarin Solder Mai Haɗaka (misali, AuSn + In)

Tsarin:

Yawanci, ana amfani da AuSn a ƙarƙashin guntu don haɗakarwa mai ƙarfi, yayin da ake amfani da In a saman don haɓaka buffering na zafi.

Fa'idodi:

Yana haɗa babban aminci tare da rage damuwa, yana inganta juriyar marufi gabaɗaya, yana daidaitawa da kyau ga yanayin aiki daban-daban

3. Tasirin Ingancin Mai Sayarwa akan Aikin Na'ura

Zaɓin kayan solder da sarrafa tsari yana da tasiri sosai ga aikin electro-optical da kwanciyar hankali na dogon lokaci na na'urorin laser:

| Ma'aunin Solder | Tasiri akan Na'ura |

| Daidaiton Layer ɗin solder | Yana shafar rarrabawar zafi da daidaiton ƙarfin gani |

| Rabon rashin aiki | Babban gurɓataccen abu yana haifar da ƙaruwar juriyar zafi da kuma yawan zafi a wurare daban-daban. |

| Tsarkakakken ƙarfe | Yana tasiri ga narkewar kwanciyar hankali da yaduwar ƙarfe tsakanin abubuwa |

| Jikewar fuska ta hanyar amfani da na'urar sanyaya fuska | Yana ƙayyade ƙarfin haɗin gwiwa da kuma haɗa ƙarfin thermal |

A ƙarƙashin aiki mai ƙarfi mai ƙarfi, ko da ƙananan lahani a cikin aikin solder na iya haifar da tarin zafi, wanda ke haifar da lalacewar aiki ko gazawar na'ura. Saboda haka, zaɓar mai ƙarfi mai ƙarfi da aiwatar da ingantattun hanyoyin solder suna da mahimmanci don cimma marufi mai inganci na laser.

4. Yanayin da Ci Gaba na Nan Gaba

Yayin da fasahar laser ke ci gaba da shiga cikin masana'antu, tiyatar likita, LiDAR, da sauran fannoni, kayan solder don marufi na laser suna canzawa ta hanyoyi masu zuwa:

①Ƙarancin zafin jiki na solder:

Don haɗawa da kayan da ke da tasiri ga yanayin zafi

②solder mara gubar:

Don cika ƙa'idodin RoHS da sauran ƙa'idodin muhalli

③Kayan aikin haɗin zafi mai ƙarfi (TIM):

Don ƙara rage juriyar zafi

④Fasahar haɗa ƙananan na'urori:

Don tallafawa rage yawan aiki da haɗakarwa mai yawa

5. Kammalawa

Duk da cewa ƙanƙanta ne a girma, kayan da aka yi da ƙarfe su ne muhimman mahaɗan da ke tabbatar da aiki da amincin na'urorin laser masu ƙarfi. A cikin marufi na sandunan diode na laser, zaɓar madaidaicin mai danshi da inganta tsarin haɗin yana da mahimmanci don cimma aiki mai dorewa na dogon lokaci.

6. Game da Mu

Lumispot ta himmatu wajen samar wa abokan ciniki kayan aikin laser na ƙwararru da ingantattun hanyoyin marufi. Tare da ƙwarewa mai zurfi a fannin zaɓar kayan solder, ƙirar sarrafa zafi, da kimanta inganci, mun yi imanin cewa kowane gyare-gyare dalla-dalla yana buɗe hanyar zuwa ga ƙwarewa. Don ƙarin bayani game da fasahar marufi ta laser mai ƙarfi, jin daɗin tuntuɓar mu.

Lokacin Saƙo: Yuli-07-2025