Yi Subscribe a Social Media ɗinmu Domin Samun Labarai Masu Mahimmanci

A fannin samar da kayan aikin laser masu inganci, kula da muhalli yana da matuƙar muhimmanci. Ga kamfanoni kamar Lumispot Tech, waɗanda ke mai da hankali kan samar da laser mai inganci, tabbatar da cewa yanayin masana'antu ba shi da ƙura ba kawai misali ne ba—alƙawarin tabbatar da inganci da gamsuwar abokan ciniki ne.

Menene kayan tsaftar ɗaki?

Tufafin ɗaki mai tsafta, wanda kuma aka sani da sutturar ɗaki mai tsafta, sutturar zomo, ko kuma coveralls, tufafi ne na musamman da aka ƙera don iyakance fitar da gurɓatattun abubuwa da barbashi zuwa muhallin ɗaki mai tsafta. Dakunan tsaftacewa wurare ne da ake sarrafawa waɗanda ake amfani da su a fannoni na kimiyya da masana'antu, kamar masana'antar semiconductor, fasahar kere-kere, magunguna, da sararin samaniya, inda ƙananan matakan gurɓatattun abubuwa kamar ƙura, ƙwayoyin cuta masu iska, da barbashi masu iska suna da mahimmanci don kiyaye inganci da amincin kayayyaki.

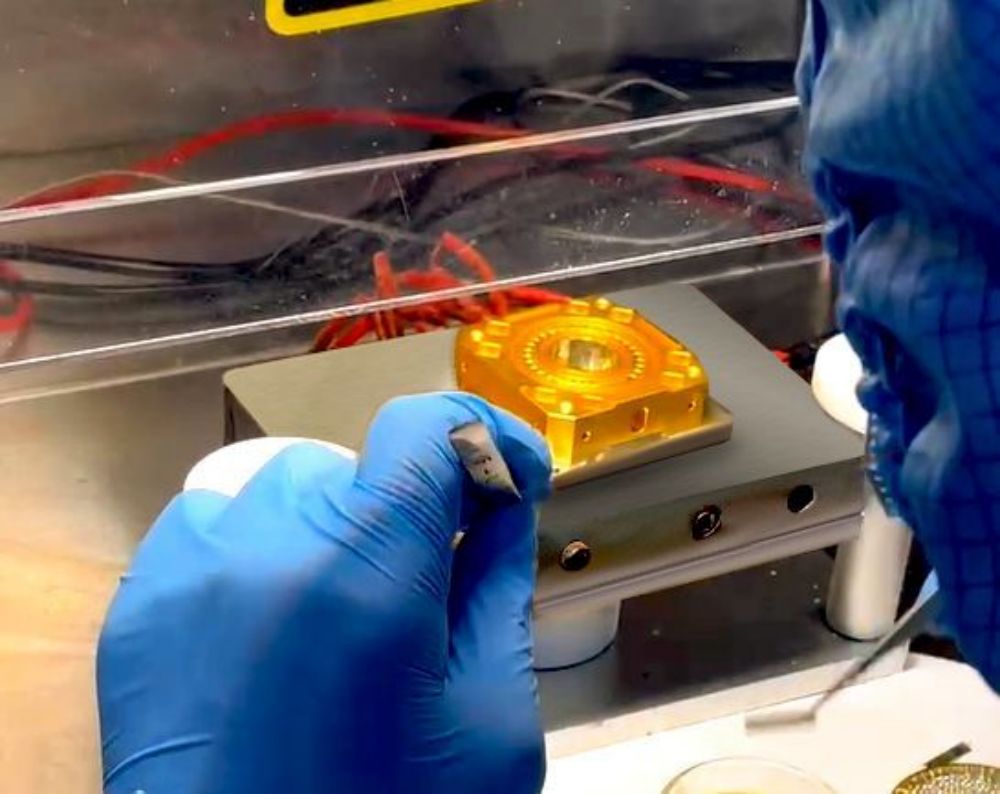

Ma'aikatan bincike da ci gaba a Lumispot Tech

Dalilin da Yasa Ake Bukatar Tufafin Ɗaki Mai Tsafta:

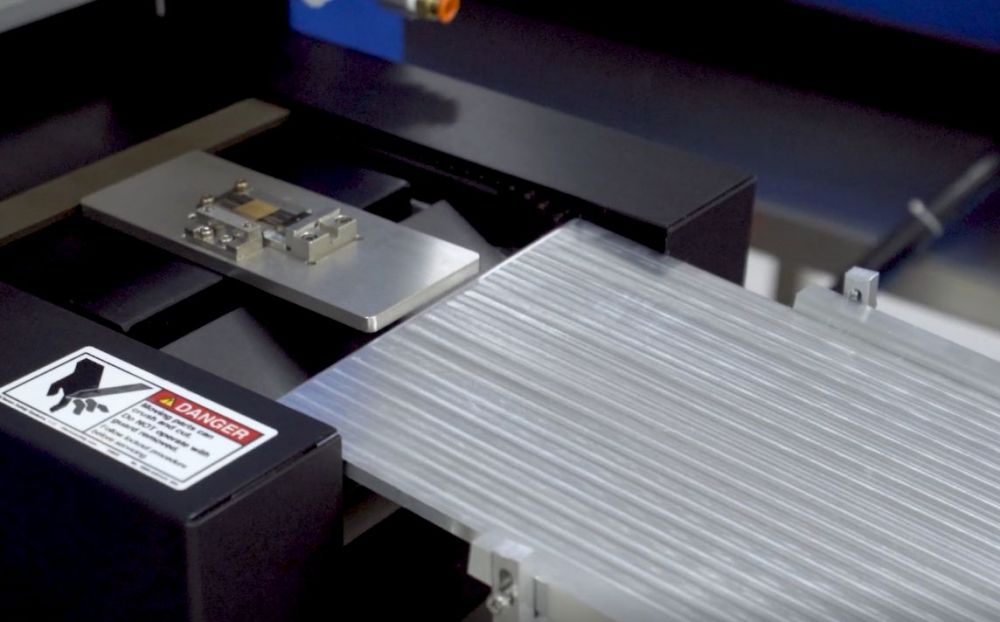

Tun lokacin da aka kafa kamfanin Lumispot Tech a shekarar 2010, ta aiwatar da wani tsari na zamani wanda ba ya ƙura a masana'antu a cikin gininta mai fadin murabba'in ƙafa 14,000. Duk ma'aikatan da ke shiga yankin samarwa ana buƙatar su sanya tufafin tsafta waɗanda suka dace da ƙa'ida. Wannan aikin yana nuna mana tsauraran matakan kula da inganci da kuma kula da tsarin masana'antu.

Muhimmancin tufafin da ba su da ƙura a wurin bitar ya fi bayyana a cikin waɗannan fannoni:

Dakin Tsafta a Lumispot Tech

Rage Wutar Lantarki Mai Tsayi

Yadi na musamman da ake amfani da su a cikin tufafin tsafta galibi suna ɗauke da zare mai jurewa don hana taruwar wutar lantarki mai tsauri, wanda zai iya lalata abubuwan lantarki masu mahimmanci ko kunna abubuwa masu ƙonewa. Tsarin waɗannan tufafin yana tabbatar da cewa an rage haɗarin fitar da wutar lantarki (ESD) (Chubb, 2008).

Kula da Gurɓatawa:

Ana yin tufafin tsafta daga masaku na musamman waɗanda ke hana zubar zare ko barbashi kuma suna tsayayya da taruwar wutar lantarki mai tsauri wanda zai iya jawo ƙura. Wannan yana taimakawa wajen kiyaye ƙa'idodin tsafta da ake buƙata a ɗakunan tsafta inda ƙananan barbashi ma za su iya haifar da mummunar illa ga ƙananan na'urori masu sarrafawa, ƙananan na'urori masu kwakwalwa, kayayyakin magunguna, da sauran fasahohi masu mahimmanci.

Ingancin Samfuri:

A cikin hanyoyin masana'antu inda kayayyaki ke da matuƙar saurin kamuwa da gurɓataccen muhalli (kamar a masana'antar semiconductor ko samar da magunguna), tufafin tsafta suna taimakawa wajen tabbatar da cewa an samar da kayayyaki a cikin yanayi mara gurɓatawa. Wannan yana da mahimmanci don aiki da amincin kayan fasaha na zamani da amincin lafiya a cikin magunguna.

Kamfanin Lumispot TechTsarin Bar na Laser DiodeTsarin Masana'antu

Tsaro da Bin Dokoki:

Amfani da tufafin tsafta shi ma an wajabta shi bisa ga ƙa'idodin da ƙungiyoyi kamar ISO (International Organization for Standardization) suka gindaya, wanda ke rarraba ɗakunan tsafta bisa ga adadin ƙwayoyin da aka yarda da su a kowace mita mai siffar cubic na iska. Ma'aikata a ɗakunan tsafta dole ne su sanya waɗannan tufafin don bin waɗannan ƙa'idodi da kuma tabbatar da amincin samfura da ma'aikata, musamman lokacin da ake sarrafa abubuwa masu haɗari (Hu & Shiue, 2016).

Rarrabuwar Tufafin Ɗakin Tsafta

Matakan Rarrabawa: Tufafin ɗaki sun fara ne daga ƙananan aji kamar Aji 10000, waɗanda suka dace da muhalli marasa tsauri, zuwa manyan aji kamar Aji 10, waɗanda ake amfani da su a cikin muhalli masu matuƙar haɗari saboda ƙwarewarsu ta sarrafa gurɓataccen ƙwayoyin cuta (Boone, 1998).

Tufafi na Aji 10 (ISO 3):Waɗannan tufafin sun dace da muhallin da ke buƙatar tsafta mafi girma, kamar samar da tsarin laser, zare na gani, da kuma na'urorin gani masu daidaito. Tufafin aji na 10 suna toshe ƙwayoyin da suka fi girman micrometer 0.3 yadda ya kamata.

Tufafi na Aji 100 (ISO 5):Ana amfani da waɗannan tufafi wajen samar da kayan lantarki, nunin faifai, da sauran kayayyakin da ke buƙatar tsafta mai yawa. Tufafin aji 100 na iya toshe ƙwayoyin da suka fi girman micrometer 0.5.

Tufafi na Aji 1000 (ISO 6):Waɗannan tufafin sun dace da muhallin da ke da matsakaicin buƙatar tsafta, kamar samar da kayan lantarki na yau da kullun da na'urorin likitanci.

Tufafi na Aji 10,000 (ISO 7):Ana amfani da waɗannan tufafi a wuraren masana'antu gabaɗaya waɗanda ba su da ƙarancin buƙatun tsafta.

Tufafin daki yawanci sun haɗa da hular rufe fuska, abin rufe fuska, takalma, kayan rufe fuska, da safar hannu, duk an tsara su ne don rufe fatar da ta fallasa gwargwadon iko da kuma hana jikin ɗan adam, wanda shine babban tushen gurɓatawa, shigar da ƙwayoyin cuta cikin muhalli mai tsari.

Amfani a Bita na Samar da Na'urar gani da Laser

A wurare kamar na'urorin gani da samar da laser, tufafin tsafta galibi suna buƙatar cika manyan ƙa'idodi, galibi na Class 100 ko ma na Class 10. Wannan yana tabbatar da ƙarancin tsangwama ga ƙwayoyin cuta da kayan gani masu mahimmanci da tsarin laser, wanda in ba haka ba zai iya haifar da matsaloli masu mahimmanci na inganci da aiki (Stowers,1999).

Ma'aikata a Lumispot Tech suna aiki a kan QCWAna amfani da diode na Laser Annular.

An yi waɗannan tufafin tsafta ne da yadi na musamman masu hana ƙura da kuma juriya ga hayaniya. Tsarin waɗannan tufafin yana da matuƙar muhimmanci wajen kiyaye tsafta. An yi amfani da siffofi kamar maƙallan hannu da idon sawu da suka matse sosai, da kuma zip ɗin da suka kai har zuwa wuyan, don ƙara girman shingen da ke hana gurɓatattun abubuwa shiga yankin da aka tsaftace.

Nassoshi

Boone, W. (1998). Kimantawa kan yadin tufafi na ɗaki/ESD: hanyoyin gwaji da sakamako. Taro na Taro na Fitar da Kaya/Electrostatic. 1998 (Cat. No. 98TH8347).

Stowers, I. (1999). Takaddun bayanai game da tsaftar gani da kuma tabbatar da tsafta. Takardun SPIE.

Chubb, J. (2008). Nazarin Tribocharging akan tufafin tsafta da ake zaune a ciki. Mujallar Electrostatics, 66, 531-537.

Hu, S.-C., & Shiue, A. (2016). Tabbatarwa da amfani da ma'aunin ma'aikata don tufafin da ake amfani da su a ɗakunan tsafta. Gine-gine da Muhalli.

Lokacin Saƙo: Afrilu-24-2024