Yi Subscribe a Social Media ɗinmu Domin Samun Labarai Masu Mahimmanci

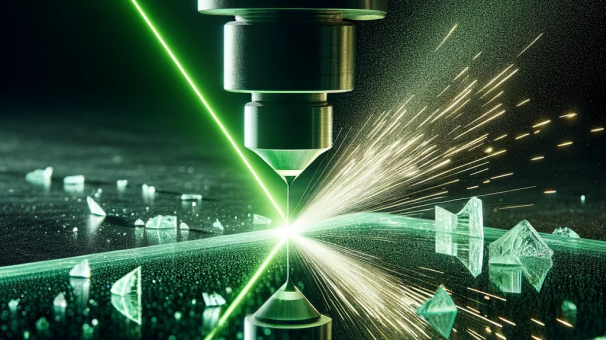

Gabatarwa ga Sarrafa Laser a Masana'antu

Fasahar sarrafa laser ta samu ci gaba cikin sauri kuma ana amfani da ita sosai a fannoni daban-daban, kamar su sararin samaniya, motoci, kayan lantarki, da sauransu. Tana taka muhimmiyar rawa wajen inganta ingancin samfura, yawan aiki, da sarrafa kansa, yayin da take rage gurɓatawa da amfani da kayan aiki (Gong, 2012).

Tsarin Laser a cikin Karfe da Kayan Aiki na Ba na Karfe ba

Babban amfani da sarrafa laser a cikin shekaru goma da suka gabata ya kasance a cikin kayan ƙarfe, gami da yankewa, walda, da rufi. Duk da haka, filin yana faɗaɗa zuwa kayan da ba na ƙarfe ba kamar yadi, gilashi, robobi, polymers, da yumbu. Kowanne daga cikin waɗannan kayan yana buɗe damammaki a masana'antu daban-daban, kodayake sun riga sun kafa dabarun sarrafawa (Yumoto et al., 2017).

Kalubale da Sabbin Dabaru a Sarrafa Gilashi ta Laser

Gilashi, tare da amfaninsa mai faɗi a masana'antu kamar su motoci, gini, da kayan lantarki, yana wakiltar wani muhimmin yanki na sarrafa laser. Hanyoyin yanke gilashi na gargajiya, waɗanda suka haɗa da kayan aikin ƙarfe ko lu'u-lu'u, suna da iyaka saboda ƙarancin inganci da gefuna masu kauri. Sabanin haka, yanke laser yana ba da madadin mafi inganci da daidaito. Wannan ya bayyana musamman a masana'antu kamar kera wayoyin komai da ruwanka, inda ake amfani da yanke laser don murfin ruwan tabarau na kyamara da manyan allon nuni (Ding et al., 2019).

Sarrafa Laser na Nau'ikan Gilashi Masu Daraja

Nau'o'in gilashi daban-daban, kamar gilashin gani, gilashin quartz, da gilashin sapphire, suna gabatar da ƙalubale na musamman saboda yanayinsu mai rauni. Duk da haka, dabarun laser na zamani kamar femtosecond laser etching sun ba da damar sarrafa waɗannan kayan daidai (Sun & Flores, 2010).

Tasirin Wavelength akan Tsarin Fasaha na Laser

Tsawon hasken laser yana tasiri sosai ga tsarin, musamman ga kayan aiki kamar ƙarfe mai tsari. An yi nazarin hasken laser da ke fitowa a cikin yankunan ultraviolet, a bayyane, kusa da nesa don mahimmancin ƙarfin su don narkewa da ƙafewa (Lazov, Angelov, & Teirumnieks, 2019).

Aikace-aikace daban-daban bisa ga tsawon raƙuman ruwa

Zaɓar tsawon laser ba wai kawai ba ne, amma ya dogara sosai da halayen kayan da kuma sakamakon da ake so. Misali, lasers na UV (tare da gajerun raƙuman ruwa) suna da kyau don sassaka daidai da ƙira da injinan micromachine, domin suna iya samar da cikakkun bayanai. Wannan ya sa su dace da masana'antar semiconductor da microelectronics. Sabanin haka, lasers na infrared sun fi inganci don sarrafa kayan da suka fi kauri saboda zurfin damar shigarsu, wanda hakan ya sa suka dace da aikace-aikacen masana'antu masu nauyi. (Majumdar & Manna, 2013). Hakazalika, lasers na kore, waɗanda galibi ke aiki a tsawon tsayi na 532 nm, suna samun matsayi a aikace-aikacen da ke buƙatar babban daidaito tare da ƙaramin tasirin zafi. Suna da tasiri musamman a cikin microelectronics don ayyuka kamar tsarin da'ira, a aikace-aikacen likita don hanyoyin kamar photocoagulation, da kuma a ɓangaren makamashi mai sabuntawa don ƙera ƙwayoyin rana. Tsawon tsayi na musamman na lasers na kore kuma yana sa su dace da alama da sassaka abubuwa daban-daban, gami da robobi da ƙarfe, inda ake son babban bambanci da ƙarancin lalacewar saman. Wannan daidaitawar lasers na kore yana nuna mahimmancin zaɓin tsawon tsayi a cikin fasahar laser, yana tabbatar da sakamako mafi kyau ga takamaiman kayan aiki da aikace-aikace.

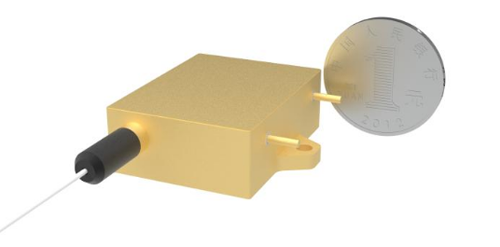

TheLaser kore 525nmwani nau'in fasahar laser ne na musamman wanda aka san shi da fitar da hasken kore a tsawon nanometer 525. Na'urorin laser kore a wannan tsawon suna samun aikace-aikace a cikin photocoagulation na retinal, inda babban ƙarfinsu da daidaitonsu suna da amfani. Hakanan suna da amfani a cikin sarrafa kayan aiki, musamman a fannoni waɗanda ke buƙatar ingantaccen aiki da ƙarancin tasirin zafi..Ci gaban diodes na laser kore akan c-plane GaN substrate zuwa tsayin raƙuman ruwa a 524–532 nm yana nuna babban ci gaba a fasahar laser. Wannan ci gaba yana da mahimmanci ga aikace-aikacen da ke buƙatar takamaiman halayen raƙuman ruwa.

Tushen Laser Mai Ci gaba da Tsarin Raƙuman Ruwa

Ana la'akari da hanyoyin laser masu ci gaba da kwararar ruwa (CW) da kuma hanyoyin laser masu siffar quasi-CW a tsayin raƙuman ruwa daban-daban kamar kusa da infrared (NIR) a tsayin 1064 nm, kore a tsayin 532 nm, da ultraviolet (UV) a tsayin 355 nm don ƙwayoyin hasken rana masu fitar da sinadarin laser. Raƙuman ruwa daban-daban suna da tasiri ga daidaitawa da inganci na ƙera (Patel et al., 2011).

Excimer Lasers don Faɗin Band Gilashi Materials

Na'urorin laser na Excimer, waɗanda ke aiki a tsawon UV, sun dace da sarrafa kayan da ke da faɗin bandgap kamar gilashi da polymer ɗin da aka ƙarfafa carbon fiber (CFRP), suna ba da daidaito mai kyau da ƙarancin tasirin zafi (Kobayashi et al., 2017).

Lasers na Nd:YAG don Aikace-aikacen Masana'antu

Ana amfani da na'urorin laser na Nd:YAG, tare da sauƙin daidaitawa dangane da daidaita tsayin tsayi, a cikin aikace-aikace iri-iri. Ikonsu na aiki a duka 1064 nm da 532 nm yana ba da damar sassauci wajen sarrafa kayan aiki daban-daban. Misali, tsawon tsayin ...

→Kayayyakin da suka shafi:Laser mai ƙarfi na Diode mai famfo CW tare da tsawon rai na 1064nm

Babban ƙarfin fiber laser walda

Ana amfani da na'urorin laser masu tsawon tsayi kusa da 1000 nm, waɗanda ke da inganci mai kyau da kuma ƙarfin aiki mai yawa, a cikin walda laser na ramin maɓalli don ƙarfe. Waɗannan na'urorin laser suna tururi da narkewar kayan aiki yadda ya kamata, suna samar da walda masu inganci (Salminen, Piili, & Purtonen, 2010).

Haɗakar Sarrafa Laser da Sauran Fasaha

Haɗakar sarrafa laser da sauran fasahohin masana'antu, kamar su rufi da niƙa, ya haifar da tsarin samarwa mafi inganci da amfani. Wannan haɗin kai yana da amfani musamman a masana'antu kamar kera kayan aiki da kayan aiki da gyaran injina (Nowotny et al., 2010).

Sarrafa Laser a Filayen da ke Tasowa

Amfani da fasahar laser ya shafi fannoni masu tasowa kamar masana'antar semiconductor, nuni, da fina-finai masu siriri, yana ba da sabbin ƙwarewa da haɓaka halayen kayan aiki, daidaiton samfura, da aikin na'urori (Hwang et al., 2022).

Abubuwan da ke Faruwa a Nan Gaba a Tsarin Laser

Ci gaban da za a samu a nan gaba a fasahar sarrafa laser zai mayar da hankali ne kan sabbin dabarun ƙera kayayyaki, inganta halayen samfura, injiniyan haɗakar kayan aiki da yawa da haɓaka fa'idodin tattalin arziki da tsari. Wannan ya haɗa da ƙera tsarin laser cikin sauri tare da porosity mai sarrafawa, walda mai haɗakarwa, da yanke zanen ƙarfe na laser (Kukreja et al., 2013).

Fasahar sarrafa Laser, tare da aikace-aikacenta daban-daban da kuma ci gaba da kirkire-kirkire, tana tsara makomar masana'antu da sarrafa kayan aiki. Sauƙin amfani da daidaitonta sun sanya ta zama kayan aiki mai mahimmanci a masana'antu daban-daban, wanda ke tura iyakokin hanyoyin masana'antu na gargajiya.

Lazov, L., Angelov, N., & Teirumnieks, E. (2019). HANYAR KIMANTAWA TA FARKO NA MUHIMMANCI MAI KYAU A CIKIN TSARI-TSARIN FASAHA NA LASER.MUHALLI. FASAHA. ALBARKAR ALBARKA. Takardun Taron Kimiyya da Aiki na Duniya. Haɗi

Patel, R., Wenham, S., Tjahjono, B., Hallam, B., Sugianto, A., & Bovatsek, J. (2011). Ƙirƙirar Laser Doping Mai Sauri Mai Sauri Ta Amfani da 532nm Continuous Wave (CW) da kuma Madogarar Laser Quasi-CW Mai Lankwasa.Haɗi

Kobayashi, M., Kakizaki, K., Oizumi, H., Mimura, T., Fujimoto, J., & Mizoguchi, H. (2017). DUV high ikon Laser aiki don gilashin da CFRP.Haɗi

Moon, H., Yi, J., Rhee, Y., Cha, B., Lee, J., & Kim, K.-S. (1999). Ingancin mitar cikin ramin da aka ninka daga na'urar laser ta Nd:YAG mai siffa mai ratsa jiki ta amfani da lu'ulu'u na KTP.Haɗi

Salminen, A., Piili, H., & Purtonen, T. (2010). Halayen high iko fiber Laser waldi.Takardun Cibiyar Injiniyoyi, Sashe na C: Mujallar Kimiyyar Injiniyan Inji, 224, 1019-1029.Haɗi

Majumdar, J., & Manna, I. (2013). Gabatarwa ga Ƙirƙirar Kayan Aiki ta Laser.Haɗi

Gong, S. (2012). Bincike da aikace-aikacen fasahar sarrafa laser mai ci gaba.Haɗi

Yumoto, J., Torizuka, K., & Kuroda, R. (2017). Ƙirƙirar Gadon Gwaji da Bayanan Bayanai na Masana'antar Laser don Sarrafa Kayan Laser.Sharhin Injiniyan Laser, 45, 565-570.Haɗi

Ding, Y., Xue, Y., Pang, J., Yang, L.-j., & Hong, M. (2019). Ci gaba a cikin fasahar saka idanu a cikin wurin don sarrafa Laser.KIMIYYA SINICA Physica, Mechanica & Astronomica. Haɗi

Sun, H., & Flores, K. (2010). Binciken Tsarin Gilashin Karfe Mai Girma Na Zr Mai Tsarin Laser.Ma'amaloli na Ƙarfe da Kayayyaki A. Haɗi

Nowotny, S., Muenster, R., Scharek, S., & Beyer, E. (2010). Haɗaɗɗen ƙwayar laser don haɗakar rufin laser da niƙa.Tarawa da Atomatik, 30(1), 36-38.Haɗi

Kukreja, LM, Kaul, R., Paul, C., Ganesh, P., & Rao, BT (2013). Dabaru Masu Sauyawa na Sarrafa Kayan Laser don Aikace-aikacen Masana'antu na Nan Gaba.Haɗi

Hwang, E., Choi, J., & Hong, S. (2022). Tsarin injinan injin da ke tasowa waɗanda ke taimakawa wajen samar da injinan injina masu inganci da inganci.Nanoscale. Haɗi

Lokacin Saƙo: Janairu-18-2024